FIRE PUMPS

FIRE ALARMS

INDUSTRIAL EQUIPMENT SOLUTIONS

HVAC SOLUTIONS

PRODUCTION LINE SOLUTIONS

CUSTOMIZED SOLUTIONS

FIRE PUMPS

When safety really matters. GC-Track accompanies you in your

daily activities, keeping you informed in real time of the current

status of your fire pumps, system pressure, water and diesel levels.

- System pressure.

- Activation of main fire pumps.

- Activations during maintenance routines.

- Switching to non-automatic mode on your controller.

- Low fuel levels in diesel engine pumps.

- Phase reversal on electric motor pumps.

- Atypical ignitions in auxiliary pumps (Jockey pump).

- Water level in tank. Low pressure and no pump start-up.

- System pressure.

- Activation of main fire pumps.

- Activations during maintenance routines.

- Switching to non-automatic mode on your controller.

- Low fuel levels in diesel engine pumps.

- Phase reversal on electric motor pumps.

- Atypical ignitions in auxiliary pumps (Jockey pump).

- Water level in tank. Low pressure and no pump start-up.

FIRE ALARMS

In case of an activation of any device GC-Track notifies you instantly,

even if someone silenced your alarm panel, this way, you will be able to

keep control of the events that happen in your facilities.

- Problem with any detection device.

- Activation of a manual station, smoke detector, UV, temperature, gas, spark, etc.

- Detection of problems in the batteries of your alarm panel.

- Alert notification with respective label.

- Problem with any detection device.

- Activation of a manual station, smoke detector, UV, temperature, gas, spark, etc.

- Detection of problems in the batteries of your alarm panel.

- Alert notification with respective label.

- No local network required.

- 24 hr. backup system.

- Maintenance mode to avoid false alarms.

- Classifies the alert according to the type of event: Fire, trouble, supervisory or security alarm.

INDUSTRIAL EQUIPMENT SOLUTIONS

Within the framework of innovation, we put at your service our set of solutions oriented to the Industry. Regardless of the area you wish to supervise, our system adapts to your most specific needs.- Compressor rooms.

- Clean rooms.

- Hydropneumatic pumps.

- System pressures.

- Humidity ranges.

- States of your systems.

- Levels of your tanks.

- Operation of your pumps.

- Operation times.

- Compressor rooms.

- Clean rooms.

- Hydropneumatic pumps.

- System pressures.

- Humidity ranges.

- States of your systems.

- Levels of your tanks.

- Operation of your pumps.

- Operation times.

HVAC SOLUTIONS

GC-Track remotely supervises the status of your HVAC system, ensuring that it is working within the appropriate time and parameters, configured for the building. Through a secure connection.- Check the status of:

- Water pumps.

- Water plant parameters.

- Cooling towers.

- Service pumps.

- Drivers.

- Water flow.

- .

- Room temperature.

- Temperature in water cooling.

- Humidity.

- Pressure in water lines.

- Differential pressure in clean areas.

- Check the status of:

- Water pumps.

- Water plant parameters.

- Cooling towers.

- Service pumps.

- Drivers.

- Water flow.

- Room temperature.

- Temperature in water cooling.

- Humidity.

- Pressure in water lines.

- Differential pressure in clean areas.

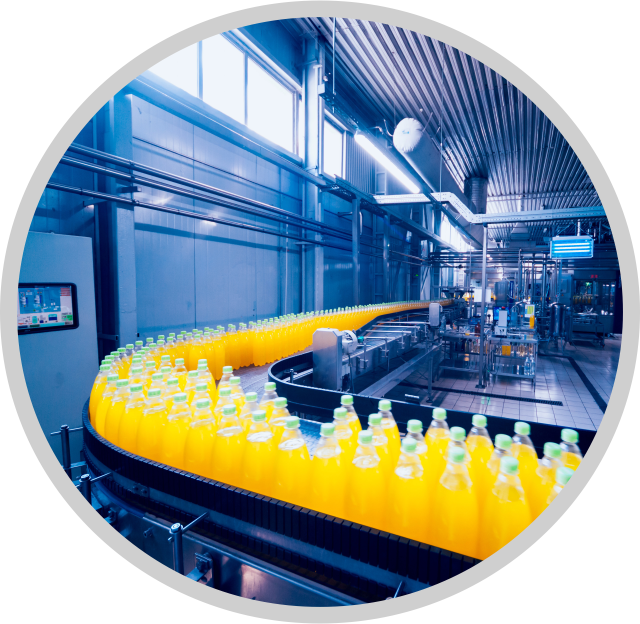

PRODUCTION LINE SOLUTIONS

Our system adapts to your production area, offering in real time the status of each key indicator for optimal decision making.- Sensors on equipment in your assembly lines.

- Supervision in production alerts.

- Machinery parameters.

- Industrial gases supervision (Vacuum, Oxygen, Compressed Air, etc.).

- Sensors on equipment in your ensamble lines.

- Supervision in production alerts.

- Machinery parameters.

- Supervision of industrial gases (Vacuum, Oxigen, Compressed air, etc.)